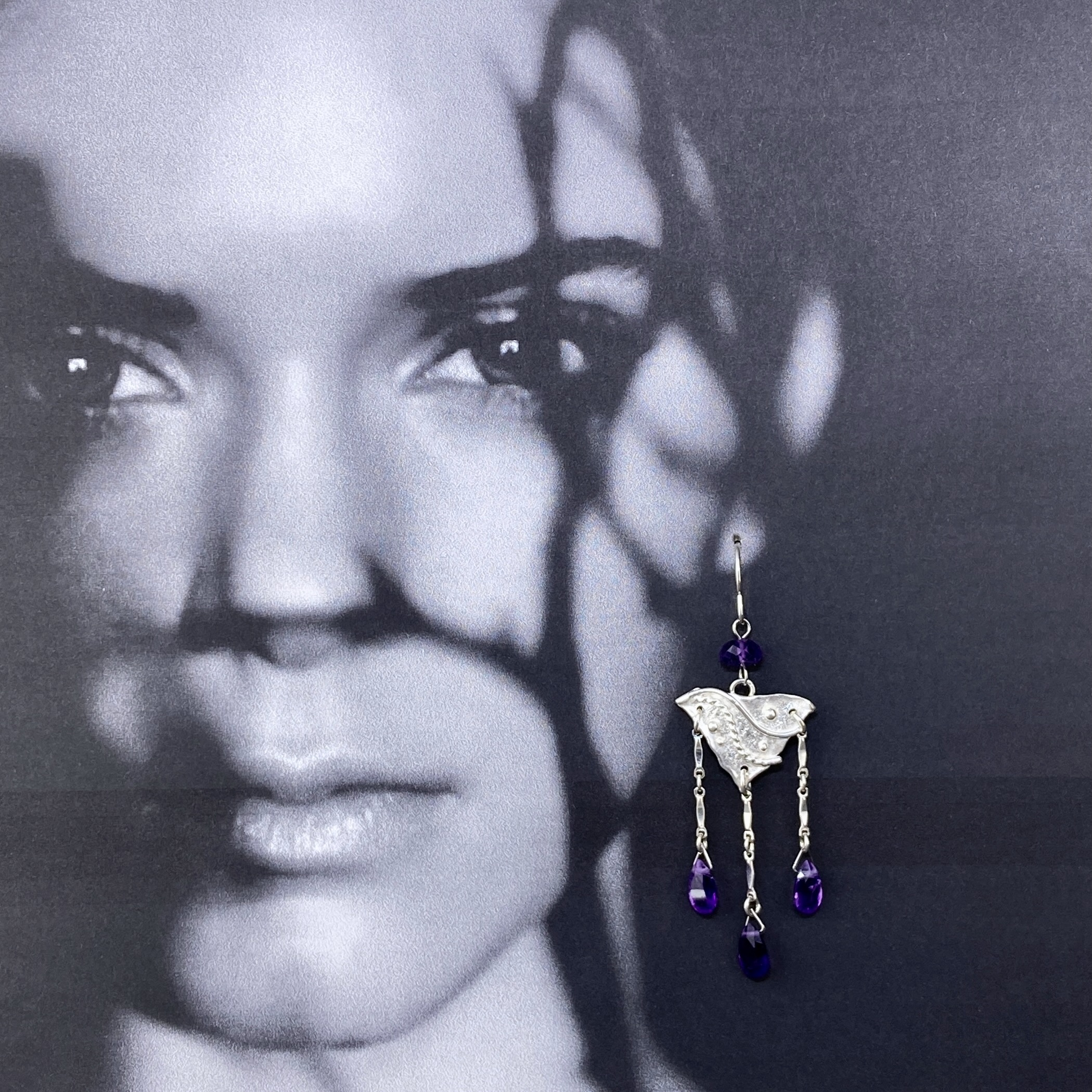

amethyst on triangle chandelier earrings

Amethyst teardrops accent a chandelier earring in the Water design group. I have created a triangular water panel with a fluid, wavy edge. Then added silver waves and pebbles. added the gemstone drops, and the hand made Argentium silver earwires.

Earrings are 6.7 cm long by 1.9 cm wide.

They weigh 6.3 grams.

WATER * I Change * FLOWING FORMLESSNESS – Transformative – Playful – Balance – Passionate

Argentium Silver is a high quality silver with a silver content of 940. It has the unique feature of having a small amount of Germanium added. Argentium Silver is whiter, harder and slower to tarnish. And it is always nickel-free.

For the ‘waves’ design (in the Water Design group) I start by imprinting Argentium silver sheet with sand – for a nice beach texture. Then I cut out matching shapes of silver for an earring pair. I always make my earrings in pairs, so that the final earrings are a ‘mirror’ pair – a left and right earring.

Next, with the softest torch, I roll the edges of the sand-textured silver pieces. I carefully and gently melt the edge, just until the silver begins to ‘roll’. Tricky – but I love the soft, organic edge.

Once I have the soft edges done, I can lay out silver waves and granules to mimic the water and pebbles of a beach shore. With a very hot torch, I fuse them permanently in place.

Then I like to ‘dap’ these little silver pieces. I gently tap the silver into a cup shape, using a curved plate and a punch. The dapping makes the silver three dimensional, instead of flat silver.

Now I choose whether this is a dangle earring or a post earring. For post earrings I decide on how the earring will best sit on the earlobe – I mark the placement of the post – and gently solder on 20 gauge Argentium silver wire. This is the standard post thickness and fits the Argentium silver butterfly perfectly.

For a dangle earring I decide whether I will drill a hole for the ear wire, or solder on a connecting loop, with which to attach either ear wires or gemstone dangles.

But, before I can attach any gemstones – Argentium silver has one extra step. It must be heated. This brings the Germanium to the surface to protect the silver – slowing down tarnish and creating a very white, scratch resistant surface.

With one final look at the silver earrings pieces, I perfect the shape and polish out any scratches or marks from the work process. Then I tumble for work hardening and to polish the Argentium silver to a bright, white finish.

These Argentium silver pieces have been textured, edges rolled, waves and granules soldered on, dapped, polished, work hardened and baked.

And, finally, the silver earrings are ready for gemstones.

Every earring goes through this entire process. It is one of my favourite designs and I enjoy making them.